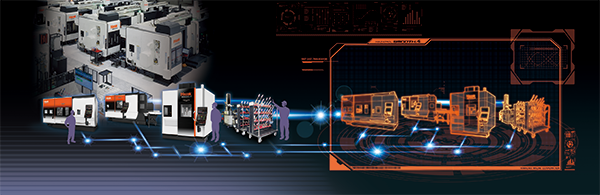

The Next generation of MAZATROL Smooth CNC control, combined with a suite of software packages which lead the industry with the practical application of Artificial Intelligence, Digital Twinning and Automation technology.

- Solid MAZATROL: uses 3D Models CAD data and AI-enhanced machining process selection to automatically program parts in MAZATROL.

- SMOOTH Ai Spindle: utilises AI technology to optimise cutting conditions by monitoring spindle vibration and adaptively altering cutting technology (Feeds & Speeds) to remove the vibration. With optimum processes achieved the cutting technology characteristics for the tool are stored to the MAZATROL or EIA (NC) program.

- Ai Thermal shield: automatically compensates the machine for temperature changes. Machine learning combined with Spatiotemporal modeling is used to increase the stability of processes with temperature change further enhancing the machine's accuracy.

Creating an identical digital copy of the machine in the office environment.

- Smooth Project Manager: transfers complete machining data including programs, fixture setup, machine models, tooling data and co-ordinate systems. It is developed to work in conjunction with SmoothCAM Ai to produce a digital twin. The data transfer can also be used in conjunction with Mazak partner solutions – CAD CAM software. This functionality saves operators time and effort and ensures accuracy of data when transferring setup information from the office to the machine.

- SMOOTH CAM Ai: MAZATROL CAM software fully supporting the Ai features of the control. This CAM package can synchronise with the physical control and create an identical programming platform on the office PC. Transferring Ai learning features, programs, tool information and setup, Solid Models of parts, solid models of Fixtures and the machine.

With a new Interface, developed in conjunction with leading robot suppliers, the Smooth Ai control can take advantage of advanced automation features for integration with articulated robots.

- Smooth Robot Cell Controller (RCC): uses advanced scheduling features to plan the machine's workload. Its functionality is capable of managing robots to load and unload tools, chuck jaws as well as material handling. Developed specifically for high mix low volume work types.

- Robot setup assist: allows operators to the creation of a Robot program directly from the machine control with a parametric interface. Simply providing basic information like the material diameter, length and clamping positions a program is automatically generated for the Robot and controlled by the Smooth Ai control.

Ergonomics play an important role in the functionality of this control. A large 19" display presents all of the critical machine data on a single page, while the tilt control panel allows for optimal positioning based on operator height.

For additional functionality, an optional second screen can provide data from SMOOTH Ai Spindle, SMOOTH PMC and SMOOTH RCC.

An intuitive multi-touch screen enables fast and smooth programming operations. An SD card allows the CNC to store up to 32GB of data.