FF-n5000/40

Compact high speed horizontal machining center for mass production FF-n5000/40

- Compact floor space

Suitable for mass production machining line of every size of parts from small size parts to large components such as cylinder blocks.

- High productivity

Reduced non-cutting time thanks to high speed acceleration and rapid traverse rate.

Feedrate (X, Y, Z-axes) : 62000 mm/min

Max. acceleration (X-axes) : 0.7 G

(Y-axes) : 1.0 G

(Z-axes) : 1.5 G

Spindle acceleration time : 1.4sec (0→12000min-1)

- High reliability

All machine linear motion is in the column to isolate the ball screws from machined chips.

Tools are directly changed to/from the spindle to the tool magazine to ensure high reliabiliy.

- Automation

Fixed table construction provides convenient automatic fixture mounting for exceptional versatility.

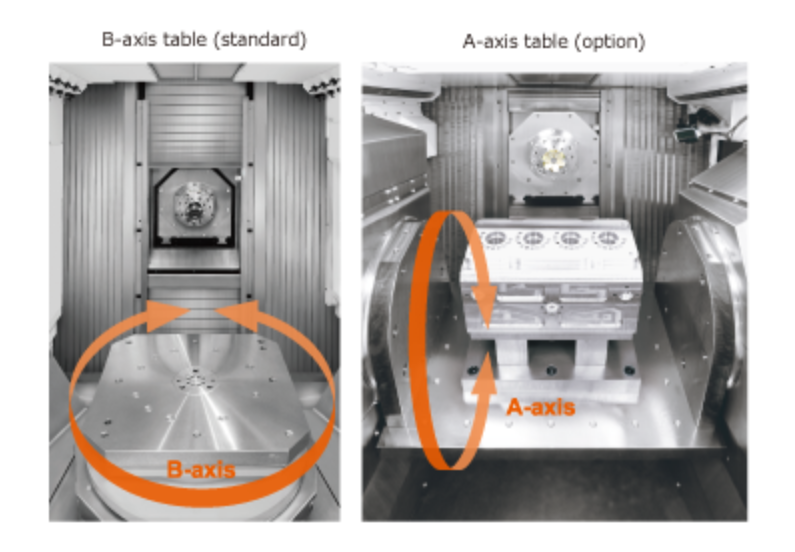

Machines with the standard B-axis machine and machines with the optional A-axis can be integrated in the same production line.

- MAZATROL SmoothC, the advanced CNC designed for ease of operation - standard equipment

- The MAZATROL SmoothC CNC is standard equipment and the Fanuc 32i is optionally available.

Note : Maximum workpiece width is 674mm because the width of front door is 674mm.(φ720 is maximum workpiece diameter including jig.)

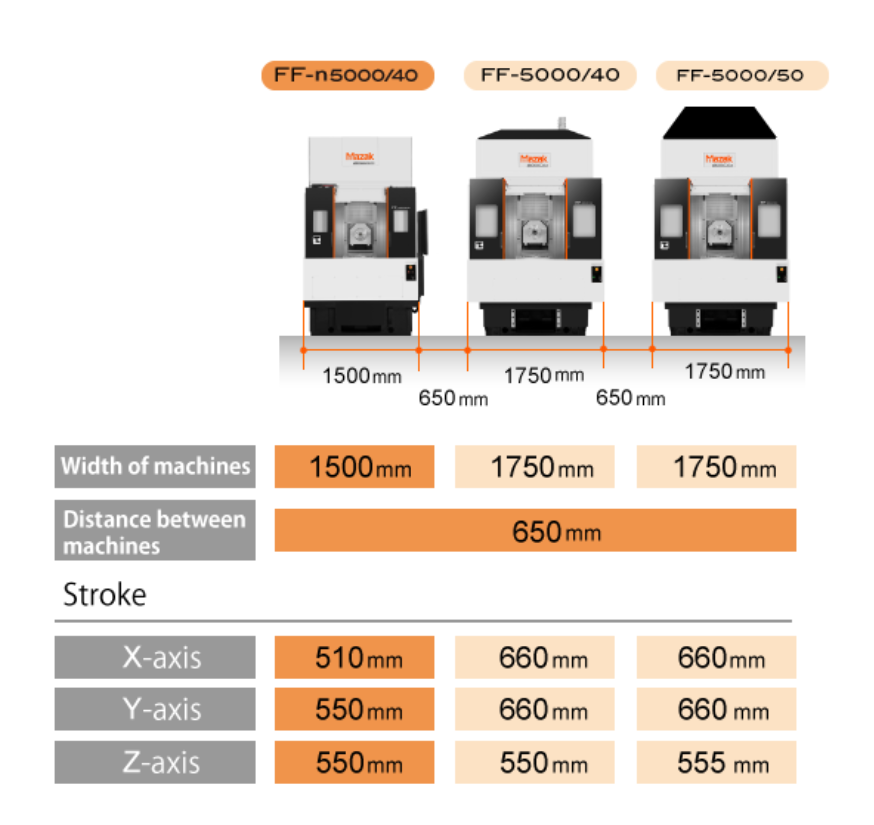

Machine Specifications

| Standard Machine | Values | |

|---|---|---|

| CAPACITY | Maximum workpiece diameter | 720 mm |

| Maximum workpiece height | 715 mm | |

| X-axis travel (column right and left) | 510 mm | |

| Y-axis travel (spindle up and down) | 550 mm | |

| Z-axis travel (table back and forth) | 550 mm | |

| SPINDLE (standard) | Spindle taper hole | 7/24 taper, No. 40 |

| Spindle speed maximum | 12,000 min-¹ | |

| FEED RATES | Rapid traverse (X/Y/Z) | 62 m/min |

| TABLE & PALLET | Pallet width | 500 mm |

| Pallet length | 500 mm | |

| ATC TOOL MAGAZINE | No. of tool pockets (standard) | 20 |

| Tool shank | MAS BT-40 /CAT-40 / HSK-A-63 | |

| MACHINE SIZE | Width | 1,500 mm |

| Length | 4,000 mm | |