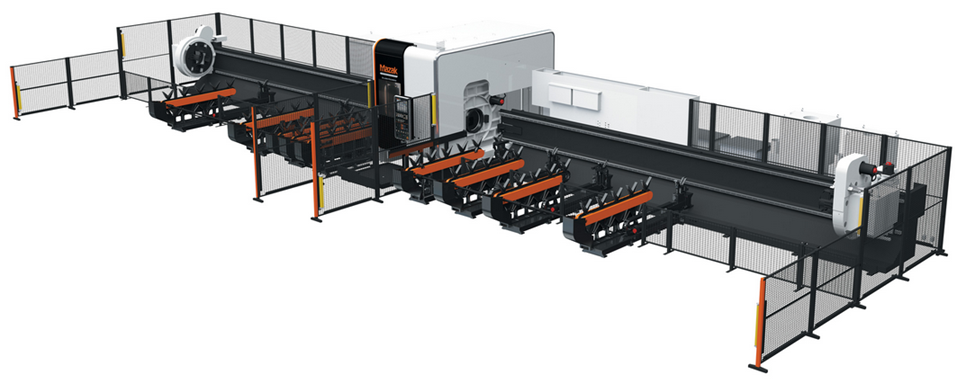

Yamazaki Mazak’s 4kW laser processing machine tool is capable of cutting large structural materials, such as pipe or tube, up to a maximum length of 8,000mm.

With options available up to more than 15,000mm, the 3D FABRI GEAR III is ideal for cutting long and heavy tube used in the construction industry, such as building structures, heating and ventilation systems, along with machinery applications including cranes and agricultural machinery.

The FABRI GEAR series have been used in a number of highly prestigious construction projects, including the Yas Marina Formula One circuit in Abu Dhabi, the national football stadium in Gdansk, Poland and the Tokyo Sky Tree, the world’s tallest broadcast tower.

The laser cutting machine is equipped with a 3D torch that enables movement on five different axes, ensuring that the machine is capable of cutting both closed and open profiles. The torch delivers industry-leading levels of accuracy by cutting vertically to ensure that the metal tubes sit flush against each other with no gaps. This reduces the need for jigs to hold the cut metal in place prior to welding and reduces the amount of weld material, offering the benefit of faster weld times and greater strength from the weld. Mazak estimates that tube cut with the 3D FABRI GEAR III can be welded and assembled twice as fast as conventionally cut tube.

In addition, highly accurate cutting is guaranteed by an automatic optimum focus positioning capability, which significantly reduces piercing time.

The latest version is capable of cutting any shaped material, from round through to square, rectangular and triangular pipe. The maximum cutting size for round workpieces is 406.4mm and 300mm for square workpieces.

It is equipped with a four-chuck system which prevents vibration and ensures highly accurate cutting. In addition, an auto-centring clamp enables fast set-up with no change in set-up from square to circular or triangular tube.

In addition, the 3D FABRI GEAR III offers a DONE-IN-ONE solution, including an optional tapping unit which can help generate significant reductions in process time by tapping in the same machine set-up as laser cutting. An optional chain conveyor is also available offering increased versatility and maximum workpiece throughput.