Yamazaki Mazak started manufacturing laser machines in the Eighties.

Yamazaki Mazak started manufacturing laser machines in the Eighties.

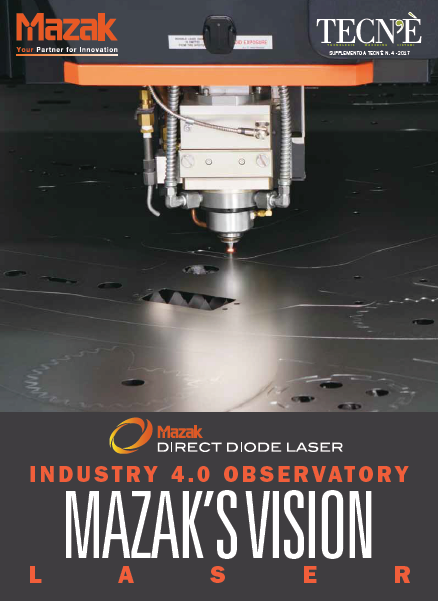

With a wide and diversified portfolio of solutions, today the company is an industry reference. From the first laser cutting machine in 1984, developments have been constant: targeted automation, 3D tools, advanced CNC technology, innovative sources and software, without overlooking ergonomics, design, safety and energy efficiency.

Mazak’s cutting products are full-featured laser machining centers:

accurate, strong and reliable over time, with multiple application opportunities. There is no limit to processing materials and geometries.

Laser opens up a world of opportunities still to be fully discovered, creating items with repeatable and unique features and offering solutions that meet the requirements of the Industry 4.0 “revolution”.

The business world is going through a historical transition and the current industrial economy will develop towards a new configuration. Needless to say, it is more and more important for all companies to ponder on the revolutionary results of technologies. In the expanded scenario of global markets, machine tools users ask for excellent products and highly reliable service, because quality is a ‘wide’ concept which pervades an entire organization. To meet the demands of such a complex market, Yamazaki Mazak, an undisputed leader in mechanical engineering, has created an organization where each ‘line of business’ is considered in its entirety,

allowing also small companies operating in local markets to leverage the most advanced technological solutions available. So, Mazak delivers a unique and consistent image to customers is different markets, offering “the essence of mechanical engineering”,i.e. “the intelligence of machine” to each customer.