Friction Stir Welding

Integration of machining and Friction Stir Welding

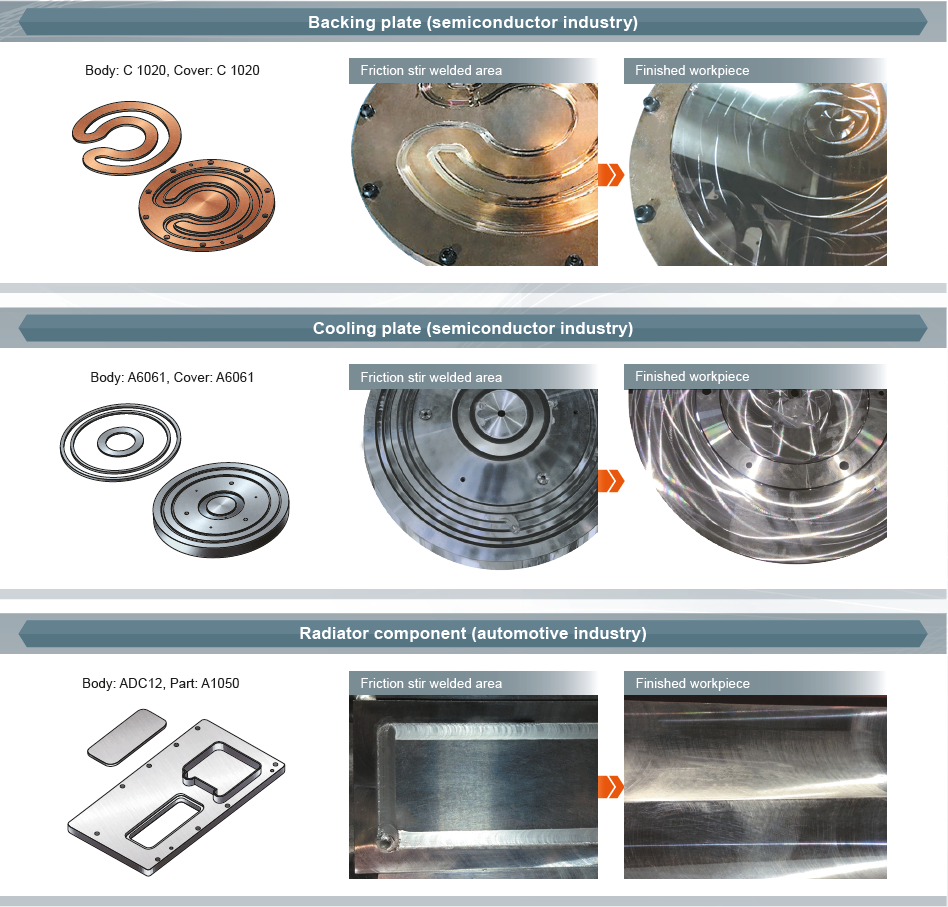

FSW unlike conventional welding, stirs material by friction for welding, producing a clean welded surface.

Features of stationary shoulder friction stir welding

FSW performs stationary shoulder friction stir welding. Unlike other friction stir welding systems that have both probe tool and shoulder turn, the shoulder is fixed to the headstock to reduce the load to the spindle bearings and to ensure a long machine service life.

Stationary shoulder friction stir welding has a smaller heat affected and softened area, to provide unsurpassed welded surfaces with minimum burrs.