What is Beam Shaping Technology, and why is it so revolutionary for laser cutting?

In the past, punching, shearing, and stamping machines were the primary tools for cutting metals. The introduction of CO2 laser cutting equipment in the 1980s improved cutting capacity and edge quality. However, in the 2010s, fiber lasers began to replace CO2 lasers in most cutting applications due to their improved speed, ease of use, and lower operating costs. Despite these advantages, CO2 lasers were still preferred for cutting medium to high-thickness metals due to their superior edge quality.

Mazak’s new Beam Shaping Technology aims to overcome the last limitation of fiber lasers by allowing them to produce the same or better edge quality as CO2 lasers, regardless of the metal thickness.

But what is Beam Shaping? It means changing the power distribution of the laser beam on the workpiece in a controllable and repeatable manner to achieve the best processing results.

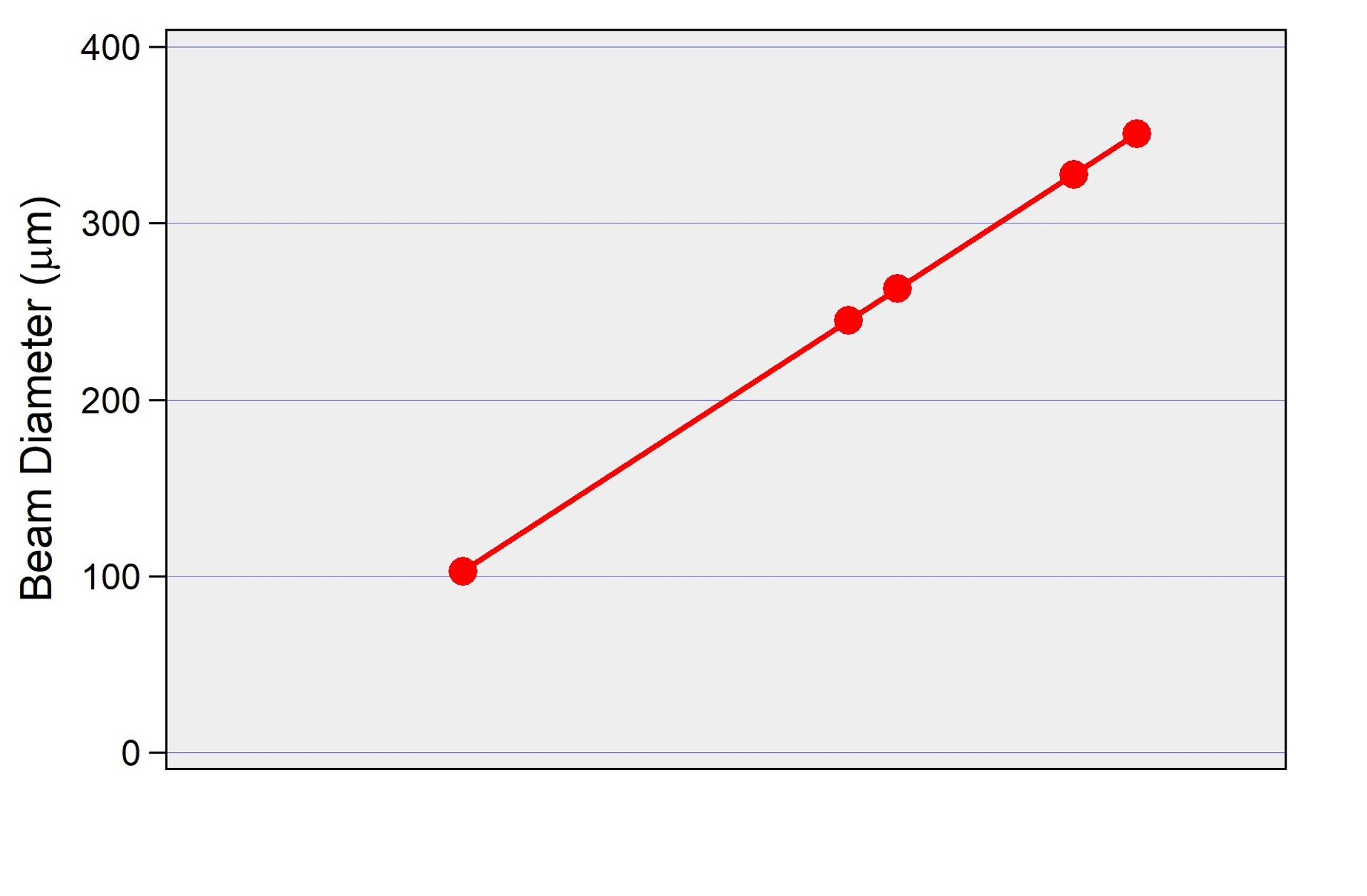

Thanks to the Variable Beam Mode function, the operator can switch from a small flat-top to a large donut with all the shapes in between, as illustrated in Figure 1.

The working principle of this Beam Shaping is a unique, patented, all-in-fiber technology that overcomes the limitations of other free-space or fused fiber combined multi-lasers approaches.

Thin & thick metal cutting

The best application of this technology is seen in thick plate cutting, where a zero taper is essential for achieving high precision and smooth edges. Traditional fiber lasers, operating with a gaussian or small flat-top mode (which is the equivalent of a CO2 TEM00 mode), produce a perfectly focused laser spot that is optimal for cutting thin metal but struggles as the metal thickness increases.

CO2 lasers, on the other hand, can operate in TEM01* mode, which is optimal for thick plate cutting.

Now, the technology introduced by Mazak can achieve and exceed the results of CO2 lasers, by allowing users to change the beam diameter size and adjust the power distribution of the focused beam, thus controlling the heat distribution on the workpiece.

Dealing with thin aluminium sheets? A small beam diameter with high power density in the centre core is best.

Thick and heavy steel plates? Using a larger diameter and directing more heat to the outer margins of the beam will provide smoother edges and overall higher accuracy. For each thickness, the optimal solution with only one laser source.

Different beams, different shapes, different models

The Beam Shaping Technology is available with different Mazak models, including the FG-400 NEO, which performs multiple processes such as 3D cutting, drilling, and chamfering on large-sized tubes and pipes, and the OPTIPLEX 3015 NEO, the 2D laser cutting machine known for its high degree of automation.

The Variable Beam Mode shows excellent cutting stability even with poor conditions of the material’s surface.

Overall, the Laser Beam Shaping Technology shows how quality, precision, adaptability, and speed can be combined in one machine, thanks to Mazak.

The advantages of Beam Shaping Technology

- Cutting speed

By changing density and beam size, we can increase the workable thickness, raising the cutting speed thanks to smaller nozzles

- Perpendicularity

The use of Beam Shaping Technology in cutting carbon steel with oxygen results in significantly improved results compared to conventional methods: the conicity of the cut is almost zero. Thanks to optimized energy distribution, it is possible to set a lower focal point, enhancing the cutting stability.

- Quality

Variable Beam control enables a superior cutting quality, ensuring better heat dispersion within the material, thus preventing the nozzle from overheating.